-

Table of Contents

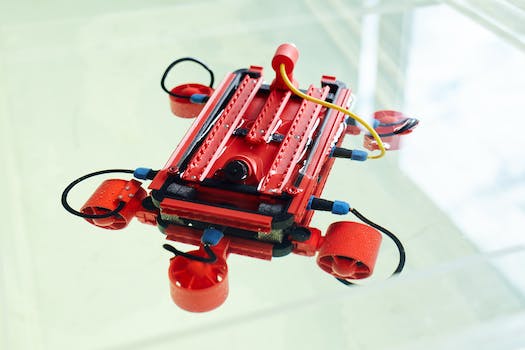

“Revolutionizing the Future: Industrial Robotics, Automation and Beyond.”

Robotics in Industry: Automation and Beyond delves into the transformative role of robotics in various industrial sectors. It explores the evolution of robotics from basic automation systems to sophisticated machines capable of performing complex tasks with precision and efficiency. The introduction of robotics has revolutionized industries, enhancing productivity, improving quality, and reducing human error. This field not only encompasses the use of robots for automation but also extends to advanced applications such as artificial intelligence and machine learning, which are set to redefine the future of industrial operations. The integration of robotics in industry is not just about automation, but it also involves the development of intelligent systems that can adapt, learn, and make decisions, taking industrial processes beyond traditional boundaries.

Exploring the Future of Industrial Robotics: Beyond Automation

The future of industrial robotics is a fascinating topic that extends far beyond the realm of automation. As we delve into the possibilities that lie ahead, it becomes clear that robotics will play an increasingly pivotal role in shaping the industrial landscape. The advent of robotics has already revolutionized the way industries operate, with automation leading the charge. However, the future holds even more exciting prospects as we move beyond automation.

The primary purpose of industrial robotics has been to automate repetitive tasks, thereby increasing efficiency and productivity. Robots have been successful in performing tasks with speed and precision that surpass human capabilities. However, the future of industrial robotics is not just about automating tasks; it’s about enhancing human capabilities and creating a symbiotic relationship between humans and machines.

One of the most exciting developments in this field is the emergence of collaborative robots, or ‘cobots’. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside humans. They are equipped with advanced sensors and AI algorithms that allow them to understand and respond to their environment. This means they can assist humans in complex tasks, learn from their human counterparts, and even adapt to changes in the work environment. The advent of cobots signifies a shift from automation to collaboration, where robots and humans work together to achieve common goals.

Another promising area of development is the integration of robotics with the Internet of Things (IoT) and big data. Industrial robots generate a wealth of data, which when combined with IoT, can provide valuable insights for improving operations. For instance, predictive maintenance, powered by machine learning algorithms, can analyze data from robots to predict equipment failures before they occur, thereby reducing downtime and increasing productivity.

Moreover, the future of industrial robotics also lies in the realm of autonomy. Autonomous robots, guided by artificial intelligence, can make decisions and perform tasks without human intervention. These robots can navigate through complex environments, adapt to changes, and even learn from their experiences. This level of autonomy goes beyond automation, as it involves robots making intelligent decisions based on their understanding of the environment.

The future of industrial robotics also holds promise for small and medium-sized enterprises (SMEs). Traditionally, industrial robots have been associated with large-scale manufacturing due to their high costs and complex programming requirements. However, the advent of affordable, easy-to-program robots is making it possible for SMEs to leverage the benefits of robotics. This democratization of robotics is expected to spur innovation and drive growth in various industries.

In conclusion, the future of industrial robotics extends far beyond automation. It involves creating a collaborative environment where humans and robots work together, leveraging big data and IoT for operational improvements, developing autonomous robots that can make intelligent decisions, and democratizing robotics for SMEs. As we move forward, it’s clear that robotics will continue to play a pivotal role in shaping the industrial landscape, driving innovation, and enhancing productivity. The future of industrial robotics is not just about doing things faster or more efficiently; it’s about doing things better, smarter, and in ways that were previously unimaginable.

The Role of Robotics in Revolutionizing Industrial Automation

The advent of robotics has brought about a significant transformation in the industrial sector, revolutionizing the concept of automation and taking it beyond the traditional boundaries. The role of robotics in industrial automation is not just about mechanizing processes; it’s about enhancing productivity, improving quality, and fostering innovation.

Industrial automation, at its core, is about optimizing processes to increase efficiency and reduce human intervention. Traditionally, this was achieved through mechanized systems that could perform repetitive tasks. However, the introduction of robotics has taken this a step further. Robots, with their precision and consistency, have the ability to perform complex tasks at a speed and accuracy that far surpasses human capabilities. This has led to a significant increase in productivity, with industries being able to produce more in less time.

But the role of robotics in industrial automation is not limited to just increasing productivity. Robots also play a crucial role in improving the quality of products. Unlike humans, robots do not tire or lose focus, which means they can maintain a consistent level of quality throughout the production process. This has led to a significant reduction in errors and defects, resulting in higher quality products.

Moreover, robotics has also opened up new avenues for innovation in industrial automation. With their advanced capabilities, robots can perform tasks that were previously considered impossible or too dangerous for humans. For instance, in the automotive industry, robots are used for tasks like welding and painting, which require a high level of precision and can be hazardous for humans. Similarly, in the pharmaceutical industry, robots are used for tasks like drug discovery and testing, which require a high level of accuracy and consistency.

Furthermore, the integration of robotics with other advanced technologies like artificial intelligence (AI) and the Internet of Things (IoT) is creating new possibilities for industrial automation. AI-powered robots can learn from their experiences and improve their performance over time, while IoT-enabled robots can communicate with each other and with other machines, creating a connected and coordinated production process.

However, the role of robotics in industrial automation is not without its challenges. One of the major concerns is the impact on jobs. While robots can perform tasks more efficiently than humans, they also have the potential to replace human workers, leading to job losses. This has led to a debate on the need for a balance between automation and job preservation.

Another challenge is the high cost of implementing robotics. While the long-term benefits of robotics in terms of increased productivity and quality are clear, the initial investment can be substantial. This can be a barrier for small and medium-sized enterprises (SMEs) that may not have the resources to invest in robotics.

Despite these challenges, the role of robotics in revolutionizing industrial automation cannot be understated. As technology continues to evolve, the capabilities of robots will only increase, making them an integral part of the industrial landscape. The key will be to leverage these capabilities in a way that enhances productivity and quality, fosters innovation, and creates a sustainable balance between automation and job preservation.

Advanced Applications of Robotics in Industrial Automation

The advent of robotics in industry has revolutionized the way we manufacture, assemble, and process goods. The integration of robotics into industrial automation has not only increased efficiency and productivity but has also opened up a plethora of advanced applications that are pushing the boundaries of what is possible.

Industrial automation, at its core, is about streamlining processes to increase efficiency, reduce errors, and improve product quality. Robots, with their precision and consistency, are perfectly suited to this task. They can work tirelessly, performing repetitive tasks with a level of accuracy that is difficult for humans to match. This has led to their widespread adoption in industries such as automotive manufacturing, where they are used for tasks ranging from welding and painting to assembly and inspection.

However, the application of robotics in industrial automation goes far beyond these traditional uses. With advancements in technology, robots are now capable of performing more complex tasks that require a higher level of intelligence and adaptability. This is where the advanced applications of robotics come into play.

One such application is in the field of collaborative robots, or cobots. These are robots designed to work alongside humans in a shared workspace. Unlike traditional industrial robots, which are often isolated from human workers for safety reasons, cobots are equipped with advanced sensors and safety features that allow them to interact with humans safely. This opens up new possibilities for automation in industries where human-robot collaboration is beneficial, such as in small parts assembly or in tasks that require a human touch.

Another advanced application of robotics is in the realm of machine learning and artificial intelligence. Robots equipped with AI capabilities can learn from their experiences, adapt to new situations, and make decisions based on the data they collect. This allows them to perform tasks that were previously thought to be the exclusive domain of humans, such as quality inspection or complex assembly. For instance, AI-powered robots can inspect products and identify defects with a level of accuracy and speed that surpasses human capabilities.

Furthermore, the integration of robotics with the Internet of Things (IoT) is creating a new wave of smart factories. In these factories, robots are connected to a network that allows them to communicate with each other and with other machines. This enables a level of coordination and efficiency that was previously unattainable. For example, if a robot detects a problem in a production line, it can alert other robots to adjust their operations accordingly, minimizing downtime and maximizing productivity.

In conclusion, the advanced applications of robotics in industrial automation are transforming the way we manufacture and process goods. From collaborative robots that work alongside humans to AI-powered robots that can learn and adapt, these advancements are pushing the boundaries of what is possible in industrial automation. As technology continues to evolve, we can expect to see even more innovative applications of robotics that will further revolutionize the industry.

The Impact of Robotics on Industry: A Look Beyond Automation

The advent of robotics in industry has been nothing short of revolutionary. It has not only transformed the way industries operate but has also opened up a plethora of opportunities for innovation and growth. While automation is often the first thing that comes to mind when we think of robotics, the impact of this technology extends far beyond that.

Automation, without a doubt, has been a game-changer. It has allowed industries to increase their productivity, reduce human error, and streamline their operations. Robots can work tirelessly, performing repetitive tasks with precision and consistency. They can also work in hazardous environments, reducing the risk of injury to human workers. However, the influence of robotics on industry is not confined to automation alone.

One of the most significant impacts of robotics is the creation of new jobs and the transformation of existing ones. While it’s true that robots can replace certain manual tasks, they also create a demand for new skills. For instance, industries now need professionals who can design, program, and maintain these robots. This has led to the emergence of new fields such as robotics engineering and robotics process automation.

Moreover, robotics has also led to the development of new products and services. For example, in the healthcare industry, robots are now used for complex surgeries, improving precision and reducing recovery time for patients. In the retail industry, robots are used for inventory management, improving efficiency and accuracy. These advancements have not only improved the quality of products and services but have also created new markets and revenue streams for businesses.

Another significant impact of robotics is on the supply chain. Robots can handle tasks such as picking, packing, and shipping with speed and accuracy, reducing the time taken to deliver products to customers. This has enabled industries to meet the growing demand for fast and efficient delivery services, giving them a competitive edge in the market.

Furthermore, robotics has also led to improvements in workplace safety. Robots can perform dangerous tasks that would otherwise put human workers at risk. For instance, in the construction industry, robots can work at great heights or in confined spaces, reducing the risk of accidents. This not only ensures the safety of workers but also reduces the cost associated with workplace injuries.

Lastly, robotics has also contributed to sustainability. Robots can operate with high efficiency, reducing waste and conserving resources. For instance, in the manufacturing industry, robots can use raw materials more efficiently, reducing waste and lowering production costs. This not only benefits the environment but also improves the bottom line for businesses.

In conclusion, while automation is a significant aspect of robotics, the impact of this technology on industry extends far beyond that. Robotics has transformed industries, creating new jobs, developing new products and services, improving supply chain efficiency, enhancing workplace safety, and contributing to sustainability. As robotics technology continues to evolve, we can expect its influence on industry to grow even further, opening up new possibilities for innovation and growth.

Q&A

1. Question: What is the role of robotics in industrial automation?

Answer: Robotics play a crucial role in industrial automation by performing tasks that are dangerous, repetitive, or difficult for humans. They increase efficiency, productivity, and accuracy, and can work continuously without fatigue.

2. Question: How has robotics changed the manufacturing industry?

Answer: Robotics has revolutionized the manufacturing industry by automating complex tasks, reducing human error, and increasing production speed. It has also improved worker safety by taking over hazardous tasks.

3. Question: What are some examples of industries that heavily rely on robotics?

Answer: Industries that heavily rely on robotics include automotive, electronics, food and beverage, pharmaceuticals, and metal fabrication. These industries use robotics for tasks like assembly, packaging, material handling, and quality inspection.

4. Question: What is the future of robotics in industry?

Answer: The future of robotics in industry is likely to involve more advanced automation, with robots becoming more intelligent and capable of learning from their experiences. This could include the use of artificial intelligence to improve decision-making and adaptability, and the development of collaborative robots that can work alongside humans.In conclusion, robotics in industry has revolutionized the way operations are conducted, leading to increased efficiency, productivity, and accuracy. Automation has reduced human error and increased speed in production lines. Beyond automation, robotics is paving the way for innovations in various industries, including healthcare, agriculture, and logistics. However, the rise of robotics also presents challenges such as job displacement and the need for new skills. Therefore, it is crucial to address these issues while harnessing the benefits of robotics in industry.